Traditional waterproofing methods encourage the use of positive-side waterproofing during construction. However, this requires access to the outside wall of the concrete structure. When access is restricted, blind or negative-side applications are often necessary. Unlike old-fashioned external membranes, which rely on an additional hurdle to shield the concrete from moisture, Krystol® actually transforms the concrete into a water-resistant barrier.

That’s because Krystol becomes an integral part of the concrete matrix when applied to existing concrete or added to the mix at time of batching.

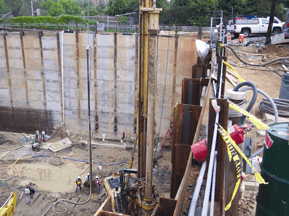

Don’t get blind-sided by space limitations – avoid applications altogether

An innovative technology is changing the way concrete structures are waterproofed and repaired. Whether your foundation needs to be damp proof or all out water proofed against hydrostatic pressure, “Integral Crystalline Waterproofing (ICW)” provides a quick and cost-saving alternative to traditional membranes. Now you can eliminate the challenges associated with blind-walls and avoid application techniques altogether during the planning stages and during construction – whether positive-side or negative-side.

Krystol® waterproofing technology eliminates the need to access the exterior surface of the structure.

Challenged for space and time?

At any time before, during or after the construction of a below-grade concrete foundation, “Integral Crystalline Waterproofing (ICW)” can solve the problem quickly and easily. Manufacturers such as Kryton International Inc, in B.C. Canada have developed concrete admixtures and cementitious surface treatments that stop water intrusion from any direction. Simply add a crystalline waterproofing admixture at the batch plant or on site – no installation is required. With the waterproofing admixture mixed right in with the concrete, a larger building footprint can also be achieved.

Unlike traditional membranes, which are subject to deterioration and abrasion from the day they are applied, integral crystalline waterproofing systems permanently become a part of the concrete matrix by reacting with water to grow long, narrow crystals to fill the pores and capillaries of the concrete mass. Crystalline surface treatments can also be brush-applied on the inside wall after the concrete pour to solve your waterproofing challenge.

Build all the way to the property line

External waterproofing membranes require room to make the application on the outside of a structure. Replace external membranes with a crystalline waterproofing admixture, such as KIM® (Krystol Internal Membrane™) and you have the flexibility to design a larger footprint – maximizing space and getting the most out of your property.

Backfill Sooner

Don’t waste time standing around while contractors apply external membranes. Crystalline technology allows you to expedite construction schedules by backfilling sooner. In addition, the best manufacturer’s crystalline products are impervious to surface abrasion, wear and tear so there is no risk of tearing and puncturing a membrane system when it comes time to backfill.

Lower the cost of labor and materials

By eliminating external membranes you also save on the cost of labor and materials that would normally be involved with such a system. In addition, even the best applicators make mistakes when they are tired, overworked or underpaid. Reduce the risk of human error by eliminating the need for application. Avoid the headaches and wasted time & money caused by insufficient seam coverage, poor surface preparation and inadequate adhesion.

Reduce future maintenance and water problems

The best crystalline products become part of the concrete matrix. Unlike traditional external membranes, true crystalline waterproofing systems are permanent and do not require replacement. In addition, the leading systems have the unique ability to self-seal hairline cracks that inevitably occur over the life of a structure – saving time, money and aggravation years into the future.

How do I know which brand is best?

Once you have decided to go with crystalline waterproofing, you are faced with a choice of products from competing manufacturers. Choosing the best one can be problematic.

The literature of one product reads very much the same as another. One must be careful not to confuse crystalline waterproofing products with products that are simply concrete densifiers or pore blockers. Watch also for products that claim to grow crystals but really only crystallize as they dry. Such products do not grow through the concrete, nor do they reactivate in the presence of water to fill cracks.

Choosing a hydrophilic waterproofing system rather than a hydrophobic system is critical to the quality of crystalline-treated concrete. Hydrophilic chemicals absorb water to create crystals that serve to block the pores and capillaries of concrete – more water equals more crystals, until no additional water can penetrate.

Silicate-based materials on the other hand form a type of hydrophobic viscous gel that repels water. They are unable to penetrate past the surface and are prone to wear and eventual deterioration. Products that contain silicates, stearates, or talc are temporary waterproofers at best, so manufacturers should offer long-term warranties and they should be able to state that their products are not based on these chemicals.

With all systems in construction, good communication and co-ordination between the manufacturer, specifier and contractor are paramount for total success.

SMART CONCRETE®

SMART CONCRETE®